Lihlahisoa

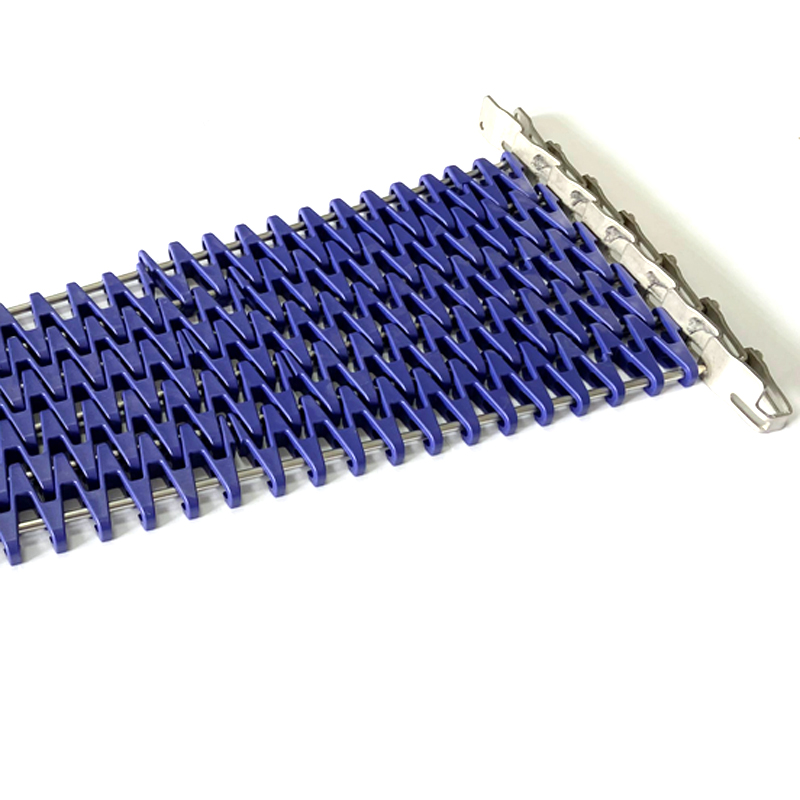

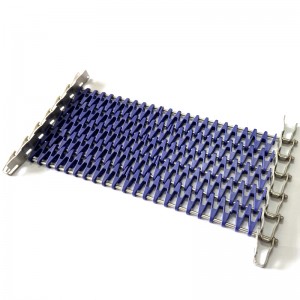

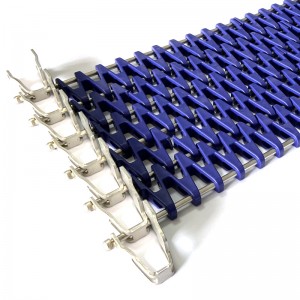

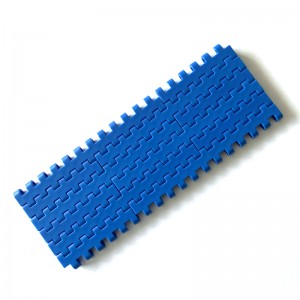

HAASBELTS Conveyor U193 Spiralox Flush Grid

Sprocket parameters

| Mofuta oa Sprocket | Palo ea meno | Bophara ba sekontiri | Ka ntle bophara | A1 | Bore |

| H (mm) | C (mm) | mm | DF (mm) | ||

| 1-U193-17-40R | 17 | 207.4 | 215.8 | 98.0 | φ40 |

| 1-U193-17-50R | φ50 | ||||

| 1-U193-17-60R | φ60 |

Tlhokomelo le tlhokomelo ea spiral mesh lebanta conveyor

Tlhahlobo ea khafetsa: Lekola khafetsa likarolo tsohle tsa sepalangoang sa lebanta la spiral mesh, ho kenyeletsoa li-bearings, liketane, mabanta a marang-rang, joalo-joalo, ho lekola hore na ha ho na ho khathala, ho hlepha kapa ho se sebetse hantle.Haholo-holo bakeng sa mabanta a letlooeng, litšila tse khomaretsoeng ho tsona li lokela ho hloekisoa kamehla ho qoba ho ama ts'ebetso ea tsona e tloaelehileng.

Lubrication: Kamehla tlotsa li-bearing le liketane tsa conveyor ea lebanta la spiral mesh ho fokotsa likhohlano le ho khathala.Bakeng sa li-bearings, mafura a tlotsang a ka eketsoa khafetsa, 'me kakaretso ea ente e ka bolela 2/3 ea sebaka se ka hare sa lebokose la ho jara;Kenya li-bearings le li-shafts ka har'a mafura a tlotsang ka linako tse ling le tse ling tse 4.

Tlhoekiso: Boloka lepanta la spiral mesh le hloekile ho thibela litšila le litšila ho kena.Nakong ea ts'ebetso ea ho tsamaisa, lintho tse kholo kapa lintho tsa tšepe tse ka har'a thepa li lokela ho qojoa hore li se ke tsa kena ka har'a conveyor ho qoba tšenyo ea thepa.

Ho tiisa: Kamehla hlahloba ho tiea ha likarolo tse fapa-fapaneng tsa lebanta la spiral mesh conveyor, 'me u li tiise ka nako e loketseng haeba ho fumanoa ho lokoloha ho itseng.

Tlhokomelo ea sesebelisoa sa ho khanna: Tlhokomelo ea khafetsa ea sesebelisoa sa drive sa spiral mesh lebanta conveyor, ho kenyelletsa le ho lekola ts'ebetso ea koloi ea koloi le se fokotsang, hammoho le ho lekola tsitsipano le lubrication ea ketane ea koloi.

Tlhokomelo ea ho koala: Kamora ho koala nako e telele, hoa hlokahala ho tsamaisa mochini ntle le mojaro nako e itseng ho netefatsa hore likarolo tsohle li sebetsa hantle pele o etsa ts'ebetso ea mojaro.Pele o emisa mochini, lisebelisoa tsohle tse ka har'a conveyor li lokela ho fetisoa ho qoba tšenyo e bakiloeng ke thepa e setseng nako e telele ka har'a conveyor.

Tlhokomelo e thibelang: Etsa moralo oa kamehla oa tlhokomelo ea thibelo, ho kenyeletsoa tlhahlobo ea khafetsa, ho tlotsa, ho hloekisa, joalo-joalo, ho thibela ho senyeha ha lisebelisoa ho etsahala.Haeba molumo leha e le ofe o sa tloaelehang kapa ho thothomela ho fumanoa ka har'a thepa, e lokela ho emisoa hang-hang bakeng sa tlhahlobo le ho rarolla mathata.

Ka ho latela mehato ea tlhokomelo e ka holimo, bophelo ba tšebeletso le ts'ebetso ea conveyor ea lebanta la spiral mesh e ka ntlafatsoa ka katleho, 'me ho hlaha ha liphoso ho ka fokotseha.

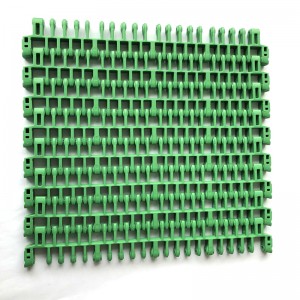

Mokhoa oa ho iketsetsa mabanta a mesh a polasetiki a modular

Theha le ho rala merero e qaqileng ea tlhahiso e ipapisitseng le litlhoko tsa bareki le litlhoko tse khethehileng tsa lisebelisoa.

Etsa liforomo, khetha lisebelisoa tsa polasetiki tse loketseng, 'me u ente li-module tsa polasetiki ka mochini o tsamaisang ente.

Arohane ho ea ka bophara le bolelele ba moreki ho theha lebanta la letlooeng la polasetiki.

MEKHATLO EA LIHLAHISO

Tsepamisa maikutlo ho faneng ka tharollo ea mong pu bakeng sa lilemo tse 5.